Triple Waste Problem: Over-Ordering, Expiry, Storage Costs

Your facility's soap dispensers are quietly draining resources in three ways most organisations overlook.

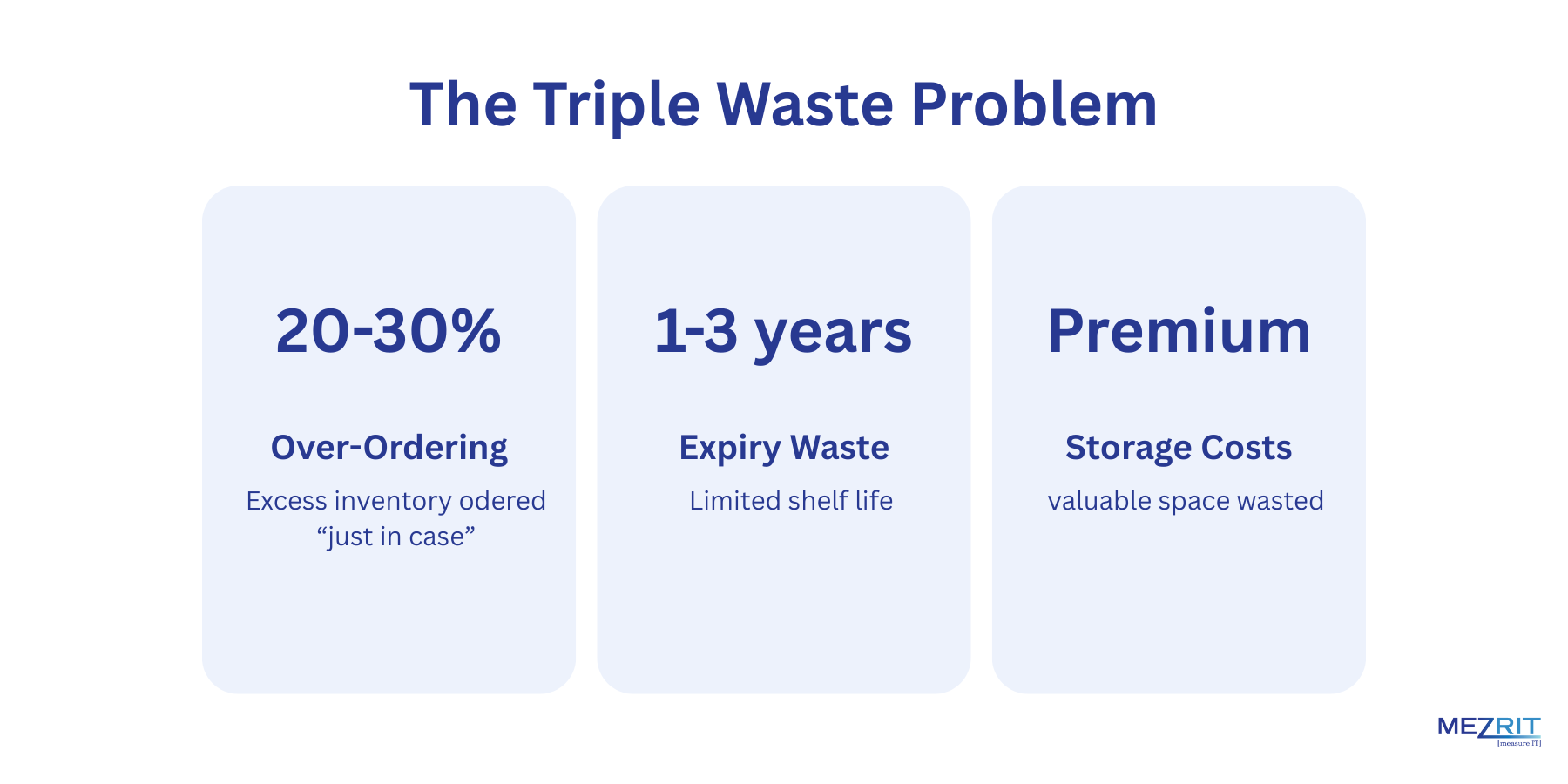

Without visibility into actual usage, facility managers are forced to make purchasing decisions in the dark. The result? A triple waste problem that impacts both your bottom line and sustainability goals.

Problem 1: Over-Ordering

When you don't know how much soap you're actually using, you default to ordering extra "just in case." Most facilities over-purchase by 20-30%, hedging against the fear of running out. That's excess manufacturing, unnecessary transportation emissions, and wasted packaging multiplied across thousands of facilities globally.

Problem 2: Expiry Waste

Here's what many don't realize: soap expires. Most liquid soaps last 1-3 years, and once opened, degradation accelerates. When you over-order, products sit in storage past their expiration dates. The result? Perfectly good soap becomes unusable waste, along with all the resources that went into producing it.

Problem 3: Storage Costs

Every bottle of excess soap consumes valuable space. In urban facilities where real estate costs premium rates, you're paying for warehouse products you may never use. Add climate control requirements to prevent degradation, and the hidden costs multiply.

The Solution: Know Your Numbers

IoT sensors installed in dispensers track real-time usage data every pump, every refill, every pattern. Suddenly, guesswork becomes precision. You see exactly how much soap is consumed, when, and where.

With this data, purchasing decisions transform. Order what you need, when you need it. No more expired products. No more wasted storage space. No more environmental impact from unnecessary production.

The sustainability wins aren't always glamorous. Sometimes they're hiding in your restroom dispensers.